Our mission

Contribute to optimize our customers´ productive processes. We are completely focused on satisfying your requirements in a flexible manner, with reliability and creativity, providing quick solutions within safety and quality standards.

Focused on Industry

Food

Food Biotechnology

Biotechnology  Energy

Energy  Mining

Mining  Machinery and Manufacturing

Machinery and Manufacturing  Naval

Naval  Paper

Paper  Oil & Gas

Oil & Gas  Chemical and Petrochemical

Chemical and Petrochemical  Metallurgical

Metallurgical  Water and Waste treatment

Water and Waste treatment  Environmental

Environmental

TECHNICAL SERVICE

Field service available in Argentina and South America Installations, starts –up, optimizations and training

Telephone assistance 24 hours

Technical integral service of centrifugal separators decanters and high speed

separators. All brands.

Technical integral service of centrifugal separators decanters and high speed

separators. All brands. Spare parts provided according specifications of each manufacturer with certified

materials, national and imported.

Spare parts provided according specifications of each manufacturer with certified

materials, national and imported. We guarantee the highest performance over standard, special and specific hard

surface trailing according to each application of decanters screw transport.

We guarantee the highest performance over standard, special and specific hard

surface trailing according to each application of decanters screw transport.

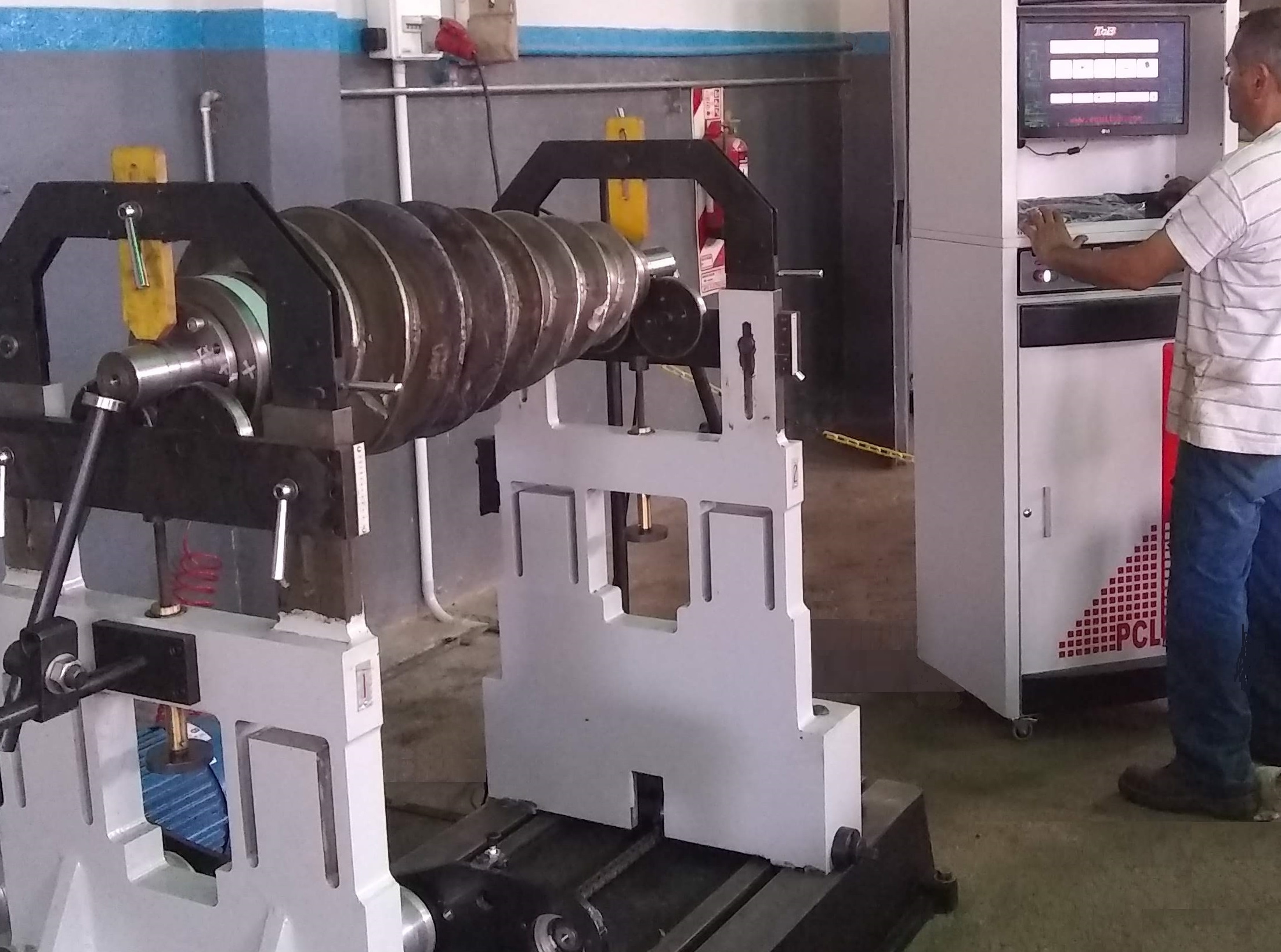

DYNAMIC BALANCING

A proper maintenance of exchangers and their regular cleaning, extends their continuous service life efficiently, without unnecessary stoppages that reduce benefits.

For that reason we offer regaskering, an integral cleaning process, both chemical

and mechanical. Fissure control, gasket replacement and hydrostatic test.

For that reason we offer regaskering, an integral cleaning process, both chemical

and mechanical. Fissure control, gasket replacement and hydrostatic test. Frame sandblasting and painting, zinc plated bars and screw.

Frame sandblasting and painting, zinc plated bars and screw.

VORTECNICA INDUSTRIAL S.A.

A TEAM WITH VOCATION

Our company is dedicated to providing industrial services in the areas of fluids, exchange and separation. In Argentina, Vortecnica Industrial and Centrisys have joined forces to offer a service of excellence.

We have a dynamic and flexible team with technicians of recognised experience and commitment, experts in centrifugal separation processes and technology, who work day by day to perfect the concept of a professional service. The close relationship between the engineering, maintenance and production areas ensures a high quality and efficient service.

In recent years, Vortecnica Industrial S.A. has developed and designed the following projects:

Centrifugal slop oil separation module, transfer skid and pumping for classified area and CCM module.

Centrifugal slop oil separation module, transfer skid and pumping for classified area and CCM module. Mobile effluent treatment plant, chosen in a competition promoted by the provincial development secretariat among 130 municipalities in the province of Buenos Aires.

Mobile effluent treatment plant, chosen in a competition promoted by the provincial development secretariat among 130 municipalities in the province of Buenos Aires. Automatic differential speed control systems for centrifugal decanter separators.

Automatic differential speed control systems for centrifugal decanter separators. Design and manufacture of special mechanical parts

Design and manufacture of special mechanical parts Development of mechanical improvements in separation equipment and automatic control systems for centrifugal separators.

Development of mechanical improvements in separation equipment and automatic control systems for centrifugal separators. Plasma and haemoglobin separation plant.

Plasma and haemoglobin separation plant. Revamping in oil and animal fat plant.

Revamping in oil and animal fat plant. Slop oil treatment plants.

Slop oil treatment plants.

Download PDF to know about benefits

Download PDF to know about benefits